CALTECH ENGINEERING SERVICES

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to CALTECH ENGINEERING SERVICES

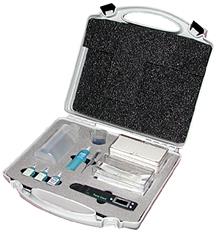

Pinhole Detector

The multi-voltage pinhole detector, which uses the wet sponge principle to detect through pinholes, cracks and damaged areas in protective coatings up to a maximum thickness of 500 microns. Pinhole Detectors or wet sponge tester detects pinholes, voids, thin spots, foreign inclusions, or contamination in coatings film. Dielectric srenth of film also refered as holiday detection.

A low voltage holiday detector / wet sponge tester operation is by the application of a wet sponge to the coating. The wetting agent penetrates any pinhole and makes a conductive path through to the substrate, the pin hole detector automatically detects this conductive path and sounds an audible alarm and also gives a visual warning by a flashing red indicator that a pinhole fault has been detected. The flaw can now be marked for repair and further testing resumed. Coating on metals prevents to corrode unless a protective coating is applied. Pinholes based on wet sponge method generally caused by air entrapment that is then released from the surface, or by the entrapment of particulates (dust, sand, etc.), which do not stay in place. High voltage holiday detector is used for testing coatings above 500µm and low voltage holiday detector (Pinhole Detector ) is used below 500µm of coating on metallc substrates.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.